- Home

- Customer Info

- How the New Treatment...

How the New Treatment Plant Process Protects Our Community

Every process has a backup for redundancy and reliability

The New Equalization Basin and additional storage in the clarifiers and other systems increase wastewater storage to provide more consistent flow and efficient operations, reduce energy cost, and decrease potential storm overflows.

New Headworks will screen and prevent debris from entering the plant. It will enhance treatment quality by removing objects such as rags, paper, plastic, and metals to prevent damage and clogging of equipment, piping, and pumps.

The primary clarifier slows down the flow allowing floaters to be skimmed off and heavy substances to sink out. A Second Primary Clarifier provides redundancy, allowing for continuous removal of solids and improved treatment. It provides additional storage capacity so other parts of the plant can be shut down for maintenance and improvements.

The secondary clarifiers provide more sinking of heavy and skimming of lighter solids.

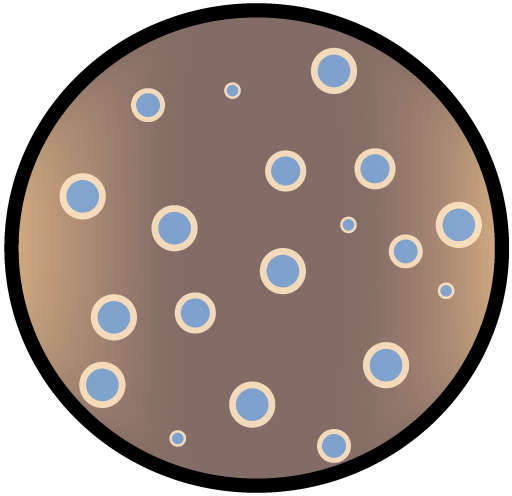

In the New Fixed Film Reactor, natural organisms that grow on plastic grids consume remaining solids.

Tertiary treatment has been substantially increased in capacity. It uses updated technology which filters extremely small particles as small as 5 microns. A human hair is 50 microns thick.

The fully treated wastewater is first disinfected. Then the disinfectant is removed so the fully treated water can be discharged safely into the Bay through a 300-foot-long outfall pipeline that lies in deep water.

The solids removed by the treatment process are heated and mixed in Digesters where it is consumed by natural organisms that reduce the volume by half. The treated solids, called biosolids are dewatered in a screw press and are sent to a landfill.

The digester produces gasses which are captured. Most is recycled by burning it to heat the digesters and some excess gas is flared off.

More odor sources are captured than previously due to additional covers and equipment connections to the central odor control system.

The Treatment Plant Upgrades Will Benefit Our Community and Environment for Decades to Come

Exceptional Treatment Quality.

Better than all health, quality and environmental requirements.

Less Odor.

More odors are captured in the central odor control system.

Modern Earthquake Resistance.

The plant is secure and built to last.

Better Treatment During Storms. Accommodates increased storm flows, improving the quality of water released into the Bay.

Fully Operational During Maintenance. All treatment process have redundancy, greatly improving reliability and allowing operators to better maintain equipment without impacting water quality.

Better Reliability and Quality.

The new Headworks, for example, screens out rags, wipes, and trash that gets into the sewer, preventing damage to the plant.

Built with the Future in Mind.

New equipment and expanded capacity will help meet stricter quality requirements for decades to come.

Improved Safety.

Safety improvements throughout the plant will protect workers, the community, and the Bay.

Built to Last

30-Inch-Thick Concrete

Equalization Storage Basin walls are 30-inches thick concrete at their base, tapering to 18-inches at their top

20-Foot Deep Footing

Some footings extend 20 feet into bedrock

465,458 lbs. of rebar

Installed to fortify the facility

2,300 Yards of Concrete

About 280 truck loads

11,400 Square Feet of soil nail walls

This required over 300 soil nails inserted into the hillside

Before Modern Wastewater Treatment There Was Stink and Sickness

As cities grew, sewage became a massive problem as depicted in this 1858 image titled "Father Thames Introducing his Offspring to the Fair city: Diphtheria, Scofula, Cholera." In the summer of 1858 all the sewage and waste of London’s roughly 2 million people spilled into the river from the city drains. In the heat and drought of that summer, it formed a slow-moving brown sludge that gave off a choking stench and was the source of mass illness. Known in history as The Great Stink, the smell of raw sewage, floating animal carcases, and rotting waste grew so intense that it led to the development of modern sanitation in London and other cities.

Sanitation Ranked as Greatest Medical Achievement

Our wastewater collection and treatment is so reliable that it is easy to forget how important it is to all our lives…

A survey by the prestigious British Medical Journal in 2007 ranked public sanitation as the most important medical achievement in the last 160+ years. Improved sewage and clean water systems have had an incredible impact on reducing disease. Public sanitation ranked higher than all other public health advances, including antibiotics, discovery of DNA and development of anesthesia.

Sewage Flowed into the Bay

Before 1953, people used septic tanks or collected and pumped untreated sewage into the Bay. In the mid-1940s, outbreaks of water-borne diseases, degradation of fishing and recreational waters, coupled with war-time industrial development and population growth triggered development of State and Regional Water Pollution Control Boards that led to the development of sewer systems across the state, including the Sausalito-Marin City Sanitary District.

Primary Treatment Only

CONSTRUCTED— 1953

CAPACITY— 2 million gallons per day

COST— $165,000

UNUSUAL— Difficult location resulted in an unusual integrated design with the clarifier above the digester. Fits within an 85-foot circle. Based to provide free sewer service to the army

DESIGNER— Jenks & Jenks

CONTRACTOR— V Maggiora & Son

Primary, Secondary Treatment, and Tertiary Treatment, Including Disinfection

CONSTRUCTED— 1985 to 1987

CAPACITY— 1.7 million gallons per day dry weather flow. 10 million gallons per day wet weather flow

COST— $8.5 million

DESIGNER— Kennedy/Jenks/Chilton

CONTRACTOR— K.G. Walters Construction

Primary and Secondary Treatment, Including

Disinfection and Advanced Tertiary Treatment

CONSTRUCTED 2017-2020

CAPACITY— 1.7 million gallons per day dry weather flow. 10 million gallons per day wet weather flow

COST— $28.2 million

DESIGNER— Woodard & Curran

CONTRACTOR— Flatiron West

Treatment Plant Construction and Operations Photos

Treatment Plant Construction Videos

Sausalito-Marin City Sanitary District

1 East Road

Sausalito, CA 94965

(415) 332-0244

info@smcsd.net

Contact Us